In the dynamic world of medical manufacturing, CNC (Computer Numerical Control) machining has emerged as a game-changer. Its precision, versatility, and efficiency have revolutionized the production of medical parts, elevating the quality and effectiveness of medical devices. In this article, we will delve into the diverse applications of CNC machining in the medical industry and explore the exciting future trends that hold immense potential for medical innovation and patient care.Get more detailed information on the website.

Applications of CNC Machining in Medical Parts:

Orthopedic Implants:

CNC machining has transformed the production of orthopedic implants, such as knee and hip replacements. By leveraging the power of CNC technology, manufacturers can fabricate implants with exceptional precision, ensuring a perfect fit and optimal functionality. The ability to create complex geometries and customize implants to suit the unique anatomical needs of patients has made CNC machining an indispensable tool in orthopedic surgeries.

Dental Prosthetics:

The field of dentistry has benefited greatly from CNC machining. From crafting crowns and bridges to manufacturing dental implants, CNC machines offer the accuracy and consistency required for producing high-quality dental prosthetics. With CNC machining, dental professionals can achieve a superior fit, improving patient comfort and oral health outcomes.

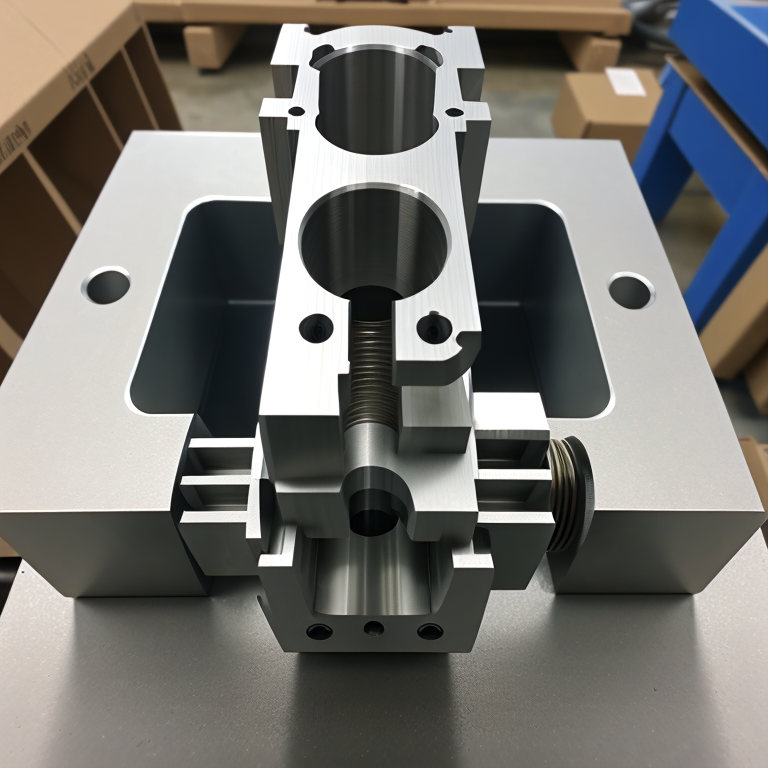

Surgical Instruments:

CNC machining plays a crucial role in the production of surgical instruments, ranging from delicate scalpels to intricate retractors. The exceptional precision and reliability of CNC machines ensure that surgical instruments are manufactured to exact specifications, empowering surgeons to perform procedures with utmost precision and enhancing patient safety.

Advantages of CNC Machining in Medical Parts:

Precision:

The hallmark of CNC machining is its unparalleled precision. In the medical field, precision is of utmost importance to ensure proper functionality and compatibility with the human body. CNC machines can achieve micro-level accuracy, resulting in medical parts that meet the stringent quality standards required for safe and effective patient care.

Customization:

CNC machining enables the production of highly customized medical parts tailored to individual patient needs. This level of customization is especially valuable in the fabrication of implants and prosthetics, as it ensures an ideal fit and promotes better treatment outcomes. By leveraging CNC technology, medical professionals can provide personalized solutions that enhance patient comfort and satisfaction.

Efficiency:

Efficiency is a key advantage of CNC machining in the medical industry. The automated nature of CNC machines, combined with their high-speed capabilities, allows for faster production times, reduced waste, and improved cost-effectiveness. This efficiency is vital in meeting the growing demand for medical parts while maintaining a focus on quality and affordability.

Future Trends in CNC Machining for Medical Parts:

Additive Manufacturing Integration:

The integration of additive manufacturing, such as 3D printing, with CNC machining holds immense promise for the future of medical part production. By combining these technologies, manufacturers can create complex geometries, rapidly prototype new designs, and fabricate patient-specific implants with unprecedented precision and efficiency.

Material Advancements:

Continual advancements in materials are paving the way for exciting possibilities in CNC machining for medical parts. Biocompatible alloys and bioresorbable polymers offer enhanced biocompatibility, durability, and patient safety. By leveraging these innovative materials, CNC machining can further improve the longevity and performance of medical devices.

Automation and AI:

Automation and artificial intelligence (AI) are poised to reshape the landscape of CNC machining in the medical industry. The integration of automated processes, coupled with AI-powered algorithms for design optimization and quality control, will streamline production, enhance efficiency, and drive innovation. This will ultimately result in faster turnaround times, improved product consistency, and greater resource optimization.

Conclusion:

CNC machining has proven to be a game-changer in the production of medical parts, enabling precise, customized, and efficient manufacturing processes. Its applications in orthopedic implants, dental prosthetics, and surgical instruments have revolutionized patient care and surgical outcomes. Looking ahead, the integration of additive manufacturing, material advancements, and automation with AI holds tremendous potential for further advancements in CNC machining for medical parts. By embracing these exciting future trends, the medical industry can continue to push boundaries, enhance patient care, and foster innovation in medical device manufacturing.